CNC Machined Aluminum Parts

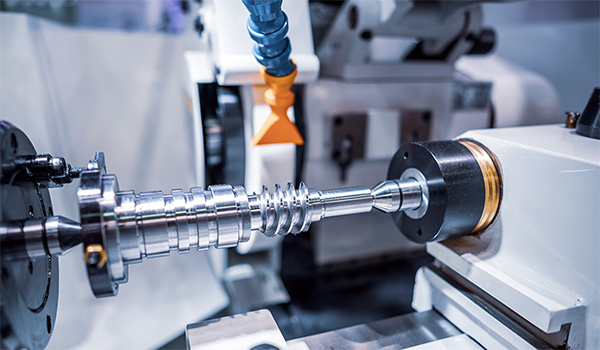

CNC machined aluminum parts are high-precision components manufactured using advanced Computer Numerical Control (CNC) technology. These parts are crafted from high-grade aluminum alloys, such as 6061, 7075, or 5083, to meet exacting industrial standards. Ideal for industries requiring lightweight yet durable solutions, CNC machined aluminum parts offer exceptional dimensional accuracy, smooth finishes, and resistance to corrosion. Whether for prototyping or mass production, these components are tailored to deliver reliability in demanding environments.

Features of cnc machined aluminum parts

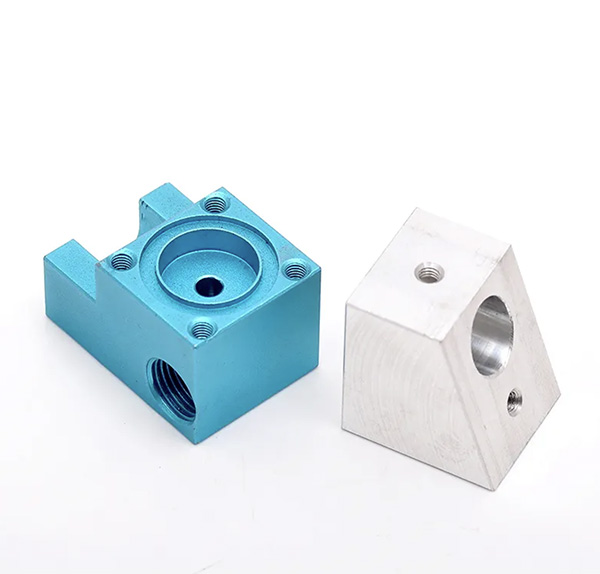

High Precision: Tolerance levels as tight as ±0.005 mm ensure flawless fit and functionality.

Lightweight & Durable: Aluminum’s strength-to-weight ratio makes parts ideal for applications where weight reduction is critical.

Corrosion Resistance: Anodized or powder-coated finishes enhance longevity in harsh environments.

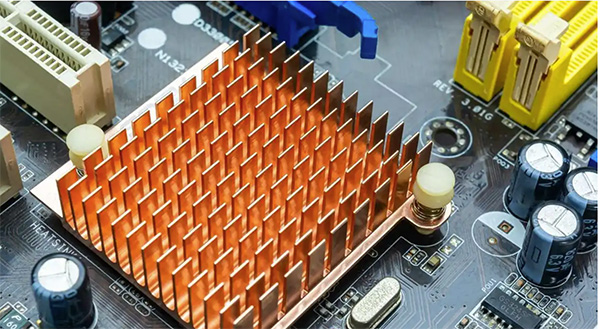

Thermal Conductivity: Efficient heat dissipation properties suit high-temperature applications.

Customizability: Compatible with complex geometries, threads, and intricate designs.

Advantages of cnc machined aluminum parts

Cost-Effective Production: CNC machining reduces material waste and labor costs.

Rapid Turnaround: Advanced machinery enables fast prototyping and bulk orders.

Versatility: Suitable for industries ranging from aerospace to consumer electronics.

Surface Finish Options: Includes milling, polishing, bead blasting, and chemical etching.

Compliance: Meets ISO 9001, AS9100, and RoHS standards for quality assurance.

Applications of cnc machined aluminum parts

Aerospace: Engine components, brackets, and UAV parts.

Automotive: Transmission systems, suspension parts, and EV battery housings.

Medical: Surgical instruments, imaging devices, and prosthetics.

Consumer Electronics: Heat sinks, enclosures, and connectors.

Industrial Machinery: Robotics, actuators, and hydraulic systems.

Parameters

| Aluminum alloy | 6061-T6, 7075-T6, 5083, 2024 |

| Tolerance | ±0.005mm to ±0.1mm (customizable) |

| Surface Finishes | Anodizing (Type II/III), Powder Coating, Polishing, Bead Blasting, Chemical Film |

| Maximum Dimensions | 500mm × 500mm × 300mm (custom sizes available) |

| Production Capacity | Prototypes (1-100pcs) to Mass Production (10,000+pcs) |