5083 Marine Grade Aluminum Plate Sheet

5083 marine grade aluminum plate has the properties of good plasticity, high specific heat, low density, low resistivity, large coefficient of linear expansion, large first-order thermal conductivity and other physical properties. In welding, friction stir welding is generally used.

Mega Aluminum has done a lot of research on marine grade aluminum, and has made great improvements in production quality. The quality of the 5083 marine grade aluminum sheet produced is more stable and the performance is better. Due to excellent product quality, our company has passed DNV, ABS, BV, CCS classification certification. The mechanical properties, welding performance and corrosion resistance of our products are up to the standards of the ship.

The marine grade aluminum sheet 5083 produced by China Aluminum of Henan Province was subjected to exfoliation corrosion test, nitric acid weightless corrosion test and welding performance test at the Physical and Chemical Testing Institute of Jiangnan Shipbuilding Co., Ltd. The test results were in line with the requirements of marine products.

1.The exfoliation corrosion test grade is N grade.

2.Nitric acid weightless corrosion test, there was almost no change before and after the sample exfoliation corrosion test, the surface was not corroded and the grade was No Appreciable attack, indicating that the material has excellent corrosion resistance.

3.Welding performance test

After the material is welded, the tensile strength of the 60mm thick 5083-O aluminum plate is 287Mpa, the tensile strength of the 25mm thick aluminium plate 5083 h112 is 283Mpa, and the tensile strength of the 6mm thick 5083 h34 aluminum plate alloy sheet is 279Mpa. Above 275 MPa, the test results show that the welds are being bent 180 degrees and the cracks are not cracking 180 degrees. Welds are fully penetrated, crack-free, and have no impurities or pores that exceed acceptable standards.

The 5083 marine grade aluminum plate we produce also has the following advantages:

1, strong anti-corrosion, durable, economic and environmental protection;

2, good arc welding performance, anodized surface appearance;

3. The product passed the China Classification Society Factory Approval Certificate and the Norwegian Classification Society Certification;

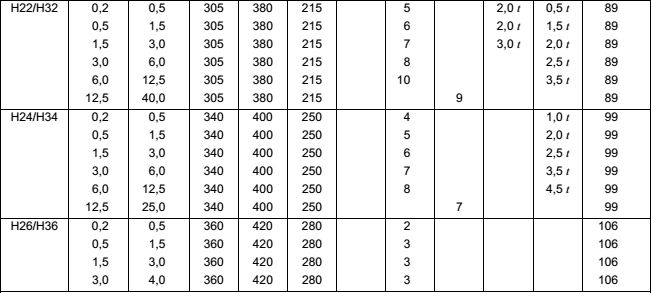

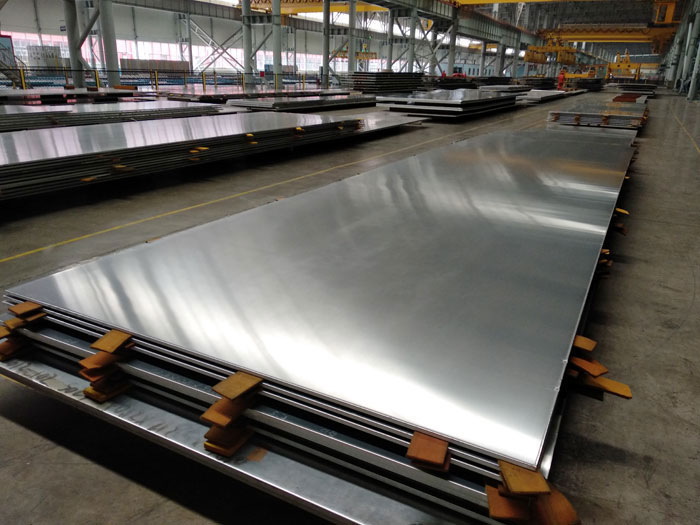

4. There is no oil spot on the surface of aluminum plate, no scratches, no waves, no roll printing, trimming and trimming, no burr;

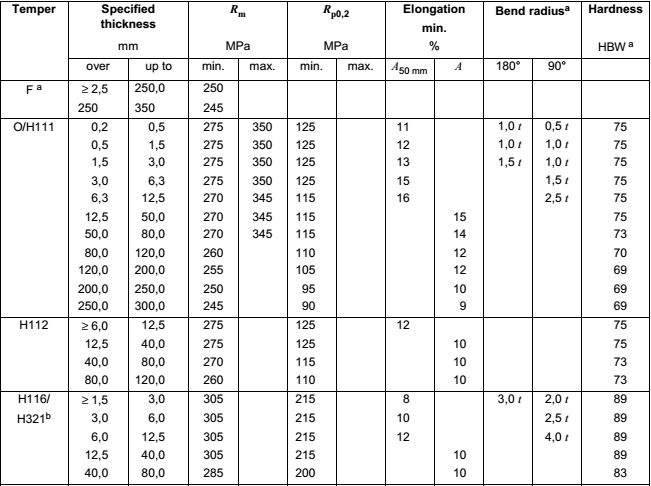

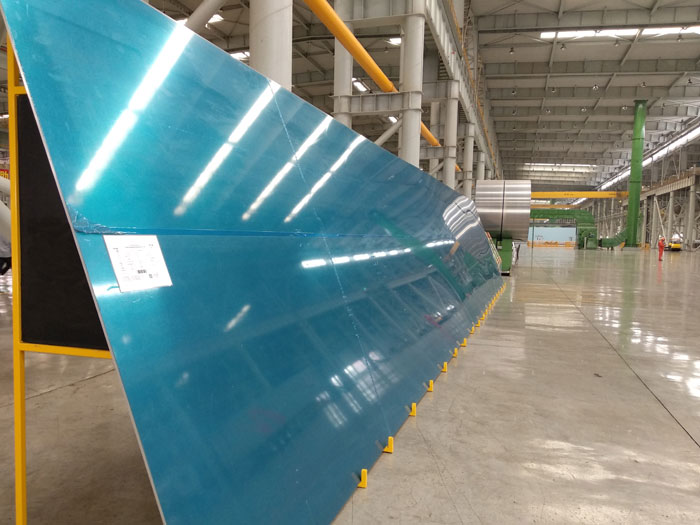

| 5083 Marine grade aluminum plate specification | ||||

| Product | Thickness(mm) | Width(mm) | Length(mm) | |

| Thick plate | 6~260 | 800~4300 | 1000~38000 | |

| Aluminum sheet | 0.2~6 | 1000~2600 | 1000~12000 | |

|

Aluminum coil |

Hot rolled coil | 2.2~12 | 1480~2600 | Coil |

| Cold rolled coil | 0.2~3.5 | 500~2600 | Coil | |

| Temper | O, H111. H112, H116, H24, H32, H321 | |||

| Certificate | DNV, NK, CCS, ABS, BV, LR | |||

| Application | Aluminum is the material of first selection of designers in high-speed ship, such as express ferries, LNG spherical tank type fluid reservoirs, hydrofoils, offshore working ships and yachts, and is widely used to shipboards, bottom plating, portholes, carrier plates and side plates of ship containers, etc. | |||

| Product Features | Long width, anti-corrosion, small elastic modulus, easy to welding, easy processing, without low temperature brittleness as well as non-magnetic. | |||

| 5083 Marine grade aluminum plate specification | ||||

| Product | Thickness(mm) | Width(mm) | Length(mm) | |

| Thick plate | 6~260 | 800~4300 | 1000~38000 | |

| Aluminum sheet | 0.2~6 | 1000~2600 | 1000~12000 | |

|

Aluminum coil |

Hot rolled coil | 2.2~12 | 1480~2600 | Coil |

| Cold rolled coil | 0.2~3.5 | 500~2600 | Coil | |

| Temper | O, H111. H112, H116, H24, H32, H321 | |||

| Certificate | DNV, NK, CCS, ABS, BV, LR | |||

| Application | Aluminum is the material of first selection of designers in high-speed ship, such as express ferries, LNG spherical tank type fluid reservoirs, hydrofoils, offshore working ships and yachts, and is widely used to shipboards, bottom plating, portholes, carrier plates and side plates of ship containers, etc. | |||

| Product Features | Long width, anti-corrosion, small elastic modulus, easy to welding, easy processing, without low temperature brittleness as well as non-magnetic. | |||