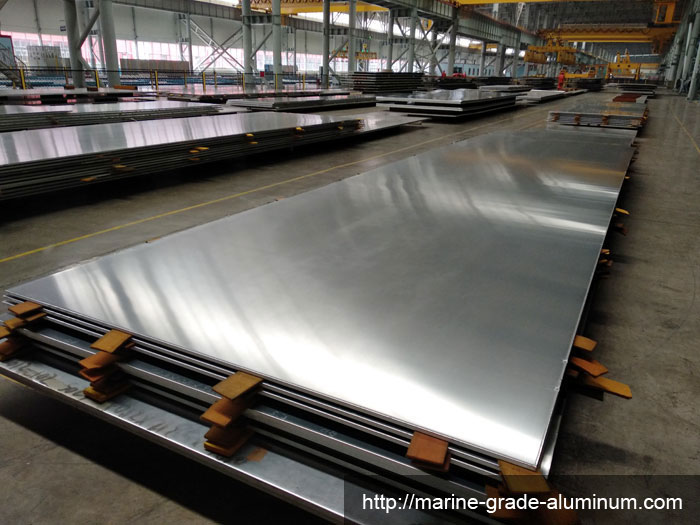

5052 h34 Marine Grade 100 Gauge Aluminum

There are five Temper of aluminum:

1. F: Free machining status

2. O: Annealed temper

3. H: work hardening temper

4. W: solution heat treatment temper

5. T: heat treatment temper

Marine grade aluminum plates are usually in the H temper, such as the 5052-h32 marine grade aluminum plate and the 5052 h34 marine grade 100 gauge aluminum. H3 is in a temper of work hardening and stable treatment. It is suitable for products with stable mechanical properties after heat treatment after heat treatment or heat treatment during processing. The H3 state is only suitable for alloys which gradually soften at room temperature. The second digit after H32, H34 indicates the degree of work hardening of the product. The work hardening of 5052 h34 marine grade 100 gauge aluminum is higher than that of H32.

The construction and working environment of the ship requires that the material should have good corrosion resistance, weldability, plasticity and certain tensile strength, yield strength, elongation, impact resistance and other properties. To meet these properties, the most applied on the ship, the best effect is 5XXX aluminum alloy, The main types of aluminum are: thick plates, plate, sheet, strip, foil, pipe, profile, bar, integral ribbed and hollow siding, free forgings and deep-worked parts (eg foam aluminum, honeycomb Aluminum) and so on. With the enlargement and light weight of the hull and the advancement of aluminum processing technology, large-scale aluminum extrusion profiles and pipes, large-scale rolled wide and thick plates, large forgings and large castings are becoming more and more widely used.

The thickness of large aluminum alloy plates for ships is generally 2-15mm, and finally up to 100mm, the thinnest is 0.2mm (thin plate) and 0.05-0.2mm (aluminum foil). The width of the aluminum strip is generally 1000-3000 mm and the width is up to 5000 mm. Large-scale castings for ships can weigh up to 500-1000kg.

Nowadays, aluminum is used more and more in the shipbuilding industry. Small self-propelled boats, large to 10,000 tons, from high-speed hovercraft to deep-water submarines, from fishing boats to mining ships are using good aluminum alloy materials as the ship's shell, the upper layer structure, various facilities, piping, etc.

If you want to purchase marine grade aluminum or have any questions about marine grade aluminum, you can call us or email us at any time.