Perforated Aluminum Plate Panel

Perforated aluminum panel (also often called perforated aluminum plate because it mostly uses punching technology) refers to a material with a rectangular cross-section made of pure aluminum or aluminum alloy materials through mechanical pressure processing (shearing or sawing).

It has beautiful appearance, elegant color and good decorative effect. It can be used in public buildings such as hotels, restaurants, cinemas, and broadcast studios and in mid-to-high-end civil buildings to improve sound quality conditions. It can also be used in various workshops, civil air defense basements, etc. as noise reduction measures.

Features of perforated aluminum panel

1) Light material, high temperature resistance, corrosion resistance, fireproof, moisture-proof, shockproof, good chemical stability, beautiful shape, elegant color, strong three-dimensional effect and good decorative effect.

2) The structure is light and stable. The application of lightweight aluminum plates combined with perforations reduces the weight of the material, which is very beneficial to the structural load-bearing and lightweight rod design.

3) The facade is simple and vivid, and patterns are formed through regular perforations, making the simple facade rich in shape, lively and vivid.

4) The perforated aluminum plate greatly reduces the shading coefficient of the glass and plays a very good role in shading, thereby reducing the impact of solar radiation on the interior, blocking direct sunlight, preventing glare, making the indoor illumination evenly distributed, and contributing to the normal operation of vision.

5) The process is simple and easy to install and maintain.

Perforated aluminum panel Classification

(1) According to the alloy composition, it is divided into: high-purity aluminum plate, pure aluminum plate, alloy aluminum plate, composite aluminum plate or welded plate and aluminum-clad aluminum plate, etc.

(2) According to thickness, it is divided into: thin plate (0.15mm-2.0mm), conventional plate (2.0mm-6.0mm), medium plate (6.0mm-25.0mm), thick plate (25mm-200mm), five-rib pattern aluminum plate and ultra-thick plate (>200mm) etc.

(3) According to the type of punching technology, it can be divided into: pattern punching mesh, forming punching mesh, heavy punching mesh, extra thin punching mesh, micro hole punching mesh, line cutting punching mesh, laser punching mesh, etc..

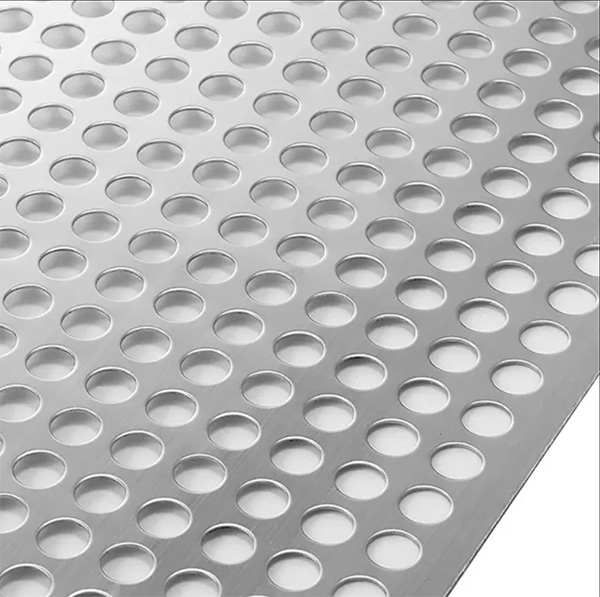

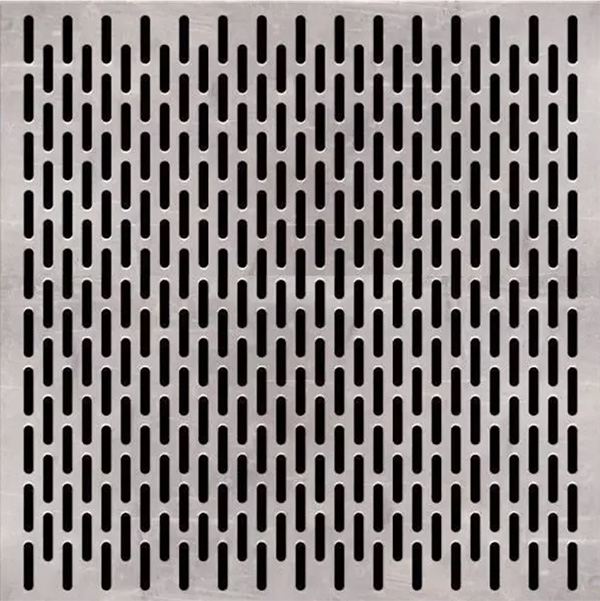

(4) According to the hole specifications, punching holes mainly include: rectangular hole, square hole, diamond hole, round hole, oblong hole, hexagonal hole, cross hole, triangular hole, long waist hole, plum blossom hole, fish scale hole, pattern hole, eight-character net, Herringbone holes, five-pointed star holes, irregular holes, drum holes, special-shaped holes, louver holes, etc. The perforation rate refers to the percentage of the total area of perforations to the entire area within the perforation area.

| Materials | Aluminum |

| Aluminium alloy | 1060, 3003 |

| Thickness | 0.3mm-10mm |

| Hole shape | Round hole,Square hole,Slotted hole,Hexagonal hole,Decorative hole |

| Width | Less than 1600mm |

| Length | Coil or customized sheets |

Perforated aluminum panel production process

(1) The most common hole diameter is 6mm and the spacing is 15mm.

(2) According to the current mechanical equipment, the maximum perforation rate can reach about 65%, and the perforated plate size is required to be within the range of 1500mm * 3000mm. If it exceeds this range, the perforation will require secondary positioning.

(3) The higher the perforation rate of perforated aluminum plates, the greater the impact on the flatness of the formed aluminum plates, and the inspection standards are lower than the corresponding regulations for normal aluminum plates.