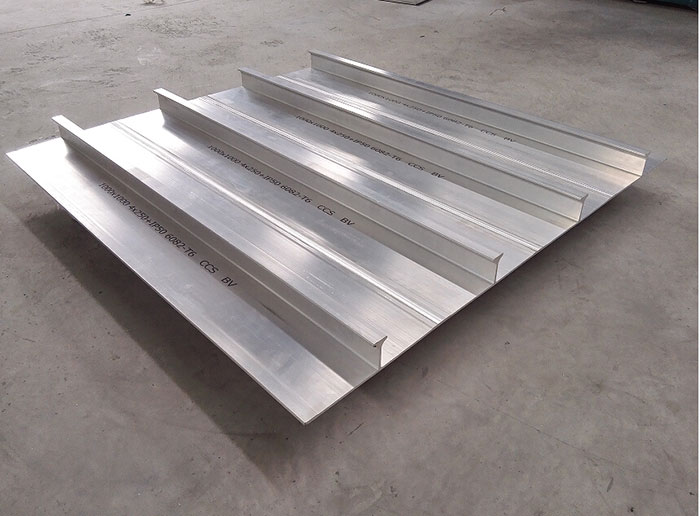

Marine Grade Ribbed Aluminum Plate Sheet

Advantages of marine grade ribbed aluminum plate

1. High geometric accuracy of ribbed aluminum sheet structure

Because the constructed sections and their positioning are determined by the extrusion die, replacing the traditional manual welding, the ribbed plane is very close to the “geometric plane”, which makes the overall stability and local stability greatly exceed the traditional Type plate.

2. The residual stress in the ribbed aluminum plate structure is very small

After theoretical discussion and experimental research on structural members of aluminum alloys, it was found that the residual stress in the extruded profiles is generally very small (less than 20 MPa). From a practical point of view, the influence on the load-bearing capacity can be ignored, so the use of ribbed aluminum plate Both the construction and the stability in use have been improved.

3. The number of structural welds is reduced with ribbed aluminium sheet

There is no large number of welded joints with ribbed aluminium sheet for connecting ordinary longitudinal profiles, and the number of welds decreases, which inevitably reduces the amount of welding operations. The number of welds is reduced, welding distortion is reduced accordingly, and the amount of work for rectification after welding is greatly reduced.

4. Improve the economic benefits of shipbuilding

A. The residual stress in the ribbed aluminium sheet structure, as described above, is very small and can be considered as not participating in the stress, which makes the ribbed aluminium sheet go from the process rod to the ideal rod. In terms of structural strength and stability, ribbed aluminium sheet is much better than conventional plates.

B. The ship repair service is extended and the total service period is increased.

C. As the ribbed aluminium sheet greatly reduce the amount of welding work, the environmental pollution caused by the welding work is reduced.

Marine grade ribbed aluminum plate size

The length of the ribbed aluminum plate is generally 6000mm. The width depends on the extrusion die, generally within 2100mm. The longitudinal direction of the ribbed aluminum plate profile is generally longitudinal. This longitudinal arrangement is suitable for the main hull and also for the superstructure.