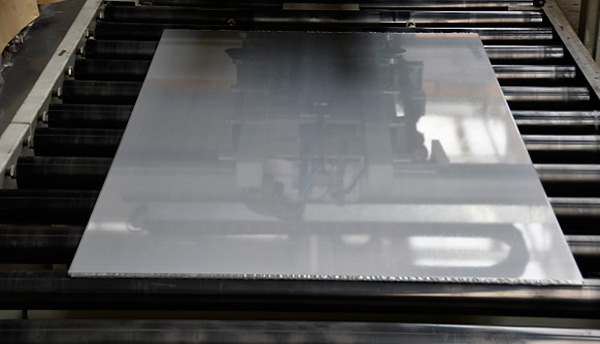

6005 Aluminium Sheet Plate

Features of 6005 Aluminum Plate

⦁ Good corrosion resistance⦁ Excellent weldability

⦁ Good cold workability

⦁ Medium strength

Applications of 6005 Aluminum Plate

Welded structural parts

Parameter

| Alloy | 6005 |

| Temper | O, T4, T6, T651 |

| Thickness(mm) | 0.3-600 |

| Width(mm) | 500-2650 |

| Length(mm) | 500-16000 |

6005 Aluminum Sheet vs. 6061 Aluminum Sheet

Both 6005 and 6061 are 6-series aluminum alloys, but there are key differences between the two.Alloy Composition

6005 Aluminum SheetThe main components are aluminum, magnesium, and silicon, with magnesium content ranging from 0.4% to 0.6%, and silicon content ranging from 0.6% to 0.9%.

6061 Aluminum Sheet

Similarly composed of aluminum, magnesium, and silicon, but with magnesium content ranging from 0.8% to 1.2%, and silicon content ranging from 0.4% to 0.8%.

Features

6005 Aluminum SheetKnown for high rust resistance and excellent weldability, it is suitable for gas welding, argon arc welding, spot welding, and roll welding. It offers medium strength and strong corrosion resistance but has poor cutting performance.

6061 Aluminum Sheet

It has higher strength, good weldability, and corrosion resistance, making it suitable for load-bearing structural materials and industrial aluminum profiles that require welding.

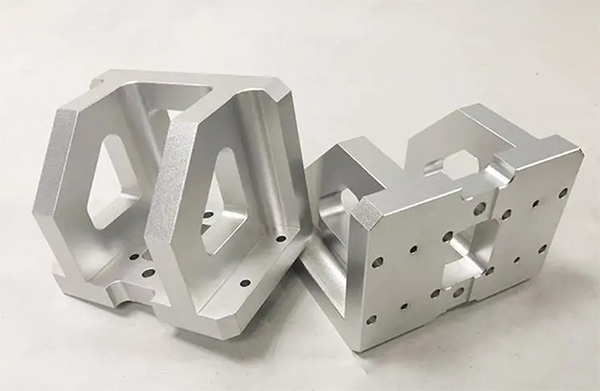

Applications

6005 Aluminum sheetCommonly used for structural parts requiring higher strength than 6063 aluminum alloy, such as ladders and TV antennas.

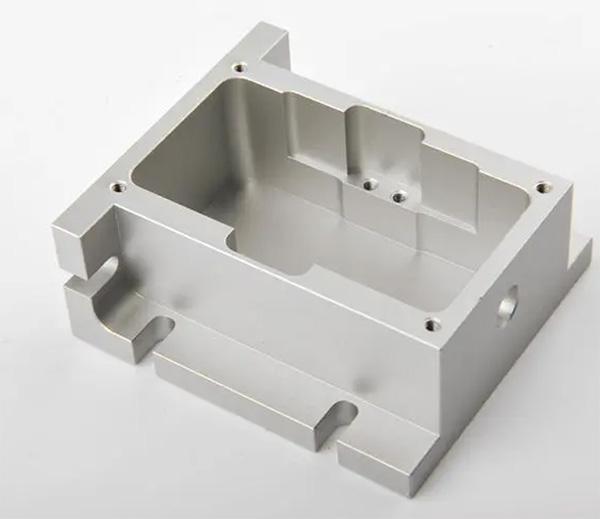

6061 Aluminum sheet

Widely used in trucks, towers, ships, trams, furniture, mechanical parts, and precision machining.