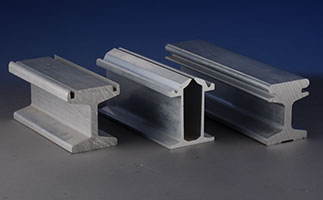

Marine Grade Aluminum i-beam

Marine grade aluminum I beam is ofen used for shipbuilding., mainly used in hull structures and generally consists of bottom plates, bottom plates, side plates, decks, bulge plates, bulwarks, bulkheads, hoardings, ribs, brackets, stringers, ribs, keels, rebars, columns and rods.It has above average corrosion resistance, good machinability, and is excellent for welding.

6061 T6 aluminum i-beam is heat-treatable, resistant to stress cracking and non-magnetic.

6063-T5 aluminum i-beam is excellent for outdoor use and architectural trim due to its superior corrosion resistance.

Marine grade aluminum i-beam Specification:

Alloy: 5083, 5086, 5383, 5059, 6061, 6063,6082,6005A

Temper: H111/H112, T5/T6

Certificate: BV /DNV /ABS/Lioyds

Thickness: 3mm---50mm

| Mechanical Properties of Marine Aluminum I Beam | |||||||

| Alloy | Form | Thickness(mm) | Temper | Rm |

Rp0.2 (Mpa) |

A% Min | |

| Min. | A₅₀ | A | |||||

| 5086 | Shapes, Bar, Tube | 3≤t≤50 | H112 | 240 | 95 | 10 | 12 |

| 5083 | Shapes, Bar, Tube Shapes, Bar, Tube | 3≤t≤50 3≤t≤50 |

H111 O and H112 |

270 270 | 110 125 | 10 10 | 12 12 |

| 5059 | Shapes, Bar, Tube | 3≤t≤50 | H112 | 330 | 200 | 10 | |

| 5383 | Shapes, Bar, Tub | 3≤t≤50 | O | 290 | 145 | 17 | 17 |

| Shapes, Bar, Tub | 3≤t≤50 | H112 | 310 | 190 | 13 | ||

| 6061 | Shapes, Bar, Tube Profiles | 3≤t≤50 3≤t≤50 |

T5 or T6 T5 or T6 |

260 245 | 240 205 | 10 | 8 4 |

| 6005A | Shapes, Bar, Tube Profiles | 3≤t≤50 | T5 | 260 | 215 | 9 | 8 |

| Shapes, Bar, Tube Profiles | 3≤t≤10 | T6 | 260 | 215 | 8 | 6 | |

| 10≤t≤50 | 250 | 200 | 8 | 6 | |||

| 6082 | Shapes, Bar, Tube Closed shapes | 3≤t≤50 3≤t≤50 |

T5 or T6 T5 or T6 |

310 290 | 260 240 | 10 | 8 5 |

| Marine Aluminum I Beam Aluminum Alloys Composition | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | Others | Alu | |

| Each | Toal | ||||||||||||

| 5083 | 0.40 | 0.40 | 0.1 | 0.4-1.0 | 4.0--4.9 | 0.05--0.25 | -- | 0.25 | 0.15 | -- | 0.05 | 0.15 | Remainder |

| 5383 | 0.25 | 0.25 | 0.20 | 0.7-1.0 | 4.0-5.2 | 0.25 | -- | 0.40 | 0.15 | -- | 0.05 | 0.15 | Remainder |

| 5086 | 0.40 | 0.50 | 0.1 | 0.2--0.7 | 3.5-4.5 | 0.05-0.25 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 5059 | 0.45 | 0.50 | 0.25 | 0.6-1.2 | 5.0-6.0 | 0.25 | - | 0.40-0.9 | 0.20 | - | 0.05 | 0.15 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 6005A | 0.50-0.9 | 0.35 | 0.30 | 0.50 | 0.40-0.7 | 0.30 | - | 0.20 | 0.10 | - | 0.05 | 0.15 | Remainder |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | - | 0.20 | 0.10 | - | 0.05 | 0.15 | Remainder |

Marine Aluminum I Beam Mould List:

| Material Code | A(mm) | B(mm) | T1(mm) | T2(mm) | R1 | R2 | G (Kg/m) |

| TP-848 | 7 | 20 | 1 | 1 | 0.092 | ||

| TP-900 | 12 | 44 | 1.4 | 1.4 | 0.246 | ||

| TP-1106 | 14.5 | 17.5 | 0.9 | 1 | 0.113 | ||

| TP-1293 | 15 | 81 | 1.2 | 1.2 | 0.364 | ||

| TP-693 | 17 | 34 | 1 | 1 | 0.5 | 0.5 | 0.211 |

| CAM_D010180 | 19.05 | 33.5 | 2 | 6.35 | 0.5 | 0.6 | 0.71 |

| TP-858 | 20 | 32 | 1 | 1 | 0.189 | ||

| TP-544 | 25 | 50.8 | 1.6 | 1.6 | 0.436 | ||

| TP-1119 | 25 | 80 | 1 | 1.4 | 0.456 | ||

| TP-85 | 35 | 180 | 3 | 3 | 3 | 1.997 | |

| CAM_D009103 | 53.01 | 37.14 | 3.21 | 4 | 1.284 | ||

| TP-585 | 70 | 100 | 5 | 5 | 1.5 | 3.11 | |

| TP-85A | 70 | 180 | 3 | 3 | 3 | 2.564 | |

| CAM_D008742 | 76.2 | 88.9 | 1.78 | 3.81 | 0.89 | 0.89 | 1.608 |

| CAM_D008677 | 76.2 | 114.3 | 6.6 | 4.5 | 7.8 | 3.3 | 4.035 |

| ALD_D002985 | 80 | 130 | 6.35 | 4.75 | 7.4 | 4.374 | |

| ALD_D000075 | 80 | 176 | 8 | 5 | 5 | 1 | 5.669 |

| CAM-253 | 80 | 160 | 10 | 10 | 8.1 | ||

| CAM_D002692 | 88.9 | 127 | 8.26 | 6.35 | 6.35 | 5.951 | |

| CAM_D010304 | 100 | 78 | 6 | 10 | 8 | 0.5 | 5.169 |

| ALD_D000072 | 100 | 270 | 10 | 6 | 5 | 1 | 9.503 |

| CAM_D002392 | 101.6 | 152.4 | 7.37 | 4.83 | 7.62 | 5.969 | |

| CAM-120 | 150 | 300 | 10 | 8 | 0.5 | 14.209 | |

| 150 | 300 | 8 | 6 | 0.5 | 14.209 |