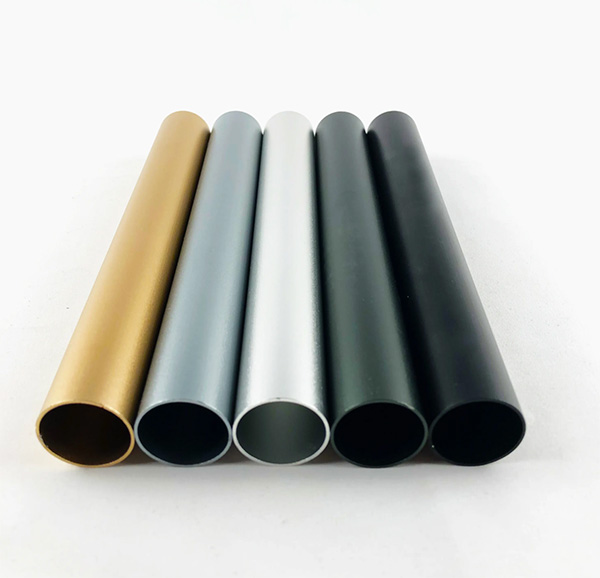

Anodized Aluminium Tube

Anodized aluminum tubes are aluminum tubes that have undergone an anodizing process, an electrolytic treatment that forms a dense, protective aluminum oxide layer on their surface.

Features of Anodized Aluminum Tubes

High-Quality Materials

Made with carefully selected, high-grade raw materials, these tubes offer exceptional pressure resistance, durability, and practicality.

Customizable Options

Customization is available based on design specifications. Multiple sizes and configurations can be tailored to meet diverse needs.

Reinforced and Thickened

With strict quality control, the production process avoids shortcuts. Standardized aluminum materials are used to ensure durability and prevent deformation.

Applications of Anodized Aluminum Tubes

Construction and Decoration

Widely used for building facades, windows, door frames, railings, and other architectural features, providing a blend of beauty and durability.

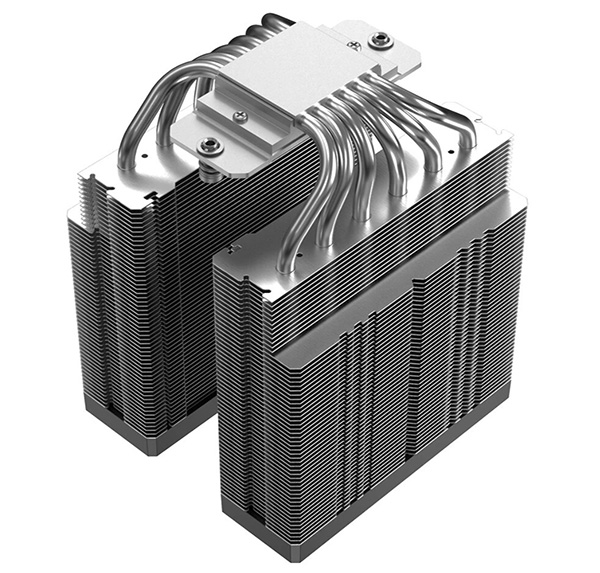

Electronics

Utilized for creating housings, heat sinks, and other components in electronic devices, thanks to their excellent thermal dissipation properties.

Furniture Manufacturing

Commonly used in crafting furniture frames, structural supports, and decorative elements.

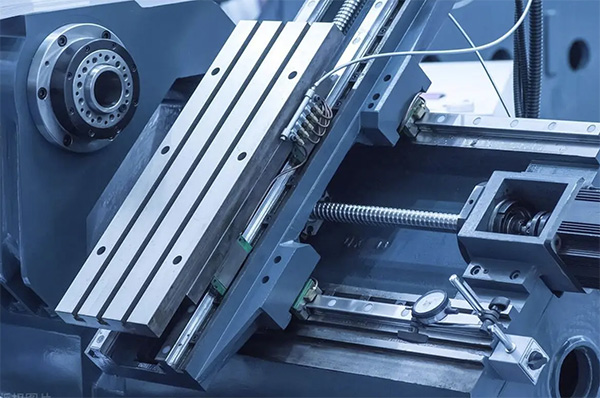

Industrial Applications

Anodized aluminum tubes are used to produce machine parts like pump bodies, valves, and piping systems across various industries.

Shipbuilding

Ideal for constructing corrosion-resistant components such as deck structures, railings, and offshore platform parts.

Piping Systems

Used in chemical, oil, and gas industries for making durable pipes and fittings, ensuring long-lasting performance in challenging environments.

| Product Name | Anodized Aluminum Tube |

| Material | 6061, 6063, 6082, etc. |

| Surface Treatment | Anodizing |

| Color | Natural, Silver, Black, Gold, Custom Colors |

| Thickness (mm) | 0.5 - 6.0 |

| Diameter (mm) | 5 - 300 |

| Length (m) | Customized according to customer needs, up to 6 meters |

| Tolerance | Thickness ±0.05mm, Diameter ±0.1mm, Length ±1mm |

| Anodized Film Thickness (μm) | 5 - 25 |

| Hardness (HV) | 80 - 150 |

| Tensile Strength (MPa) | 110 - 310 |

| Yield Strength (MPa) | 70 - 250 |

| Elongation (%) | 5 - 30 |