Marine grade aluminium 5083 used for ship side

Ship structures are often used in harsh seawater media and marine environments, so whether aluminum alloys are resistant to corrosion is one of the main signs that determine whether they can be used as marine grade aluminum alloys. It is generally required that marine grade aluminum alloy substrates and welded joints have no tendency of stress corrosion, exfoliation corrosion and intergranular corrosion in seawater and marine environment; contact corrosion, crevice corrosion and sea organism adhesion corrosion should be avoided as much as possible; small uniform corrosion is allowed.

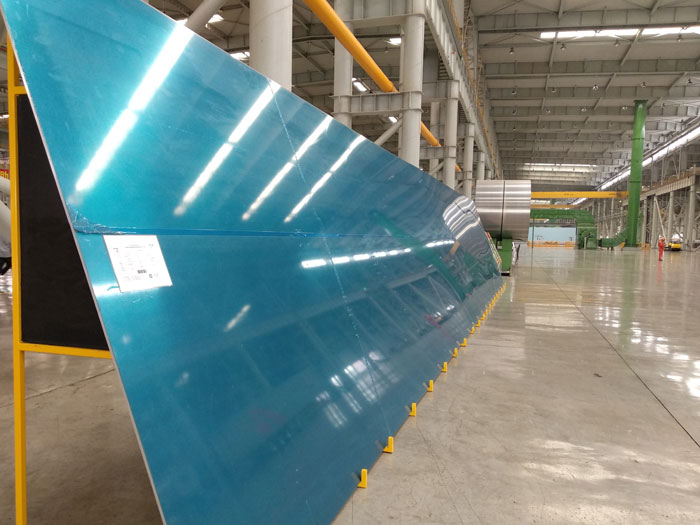

Experience has shown that any small aluminum vessel can be used for decades without any significant corrosion. The decommissioning of such vessels is usually due to technical obsolescence rather than the aging of aluminum structures. In general, the excellent maritime resistance of the 5 and 6 series aluminum-magnesium alloys, especially the seawater corrosion resistance, has been recognized. Among them, marine grade aluminium 5083 plate is a typical aluminum alloy for welding. It has the highest strength, weldability, corrosion resistance and low temperature performance in non-heat treated alloys. It can be used as a marine grade aluminum plate on the ship side.

At present, our company's marine grade aluminium 5083 plate has entered the world shipbuilding market, and has obtained the international authority certification of "China Classification Society Certification" and "Norwegian Classification Society Certification". Because of its low density and high strength, the side of the ship made with it can reduce the weight of the ship by more than 20%.

If you want to know more, please call and email us [email protected], we will be happy to help you.