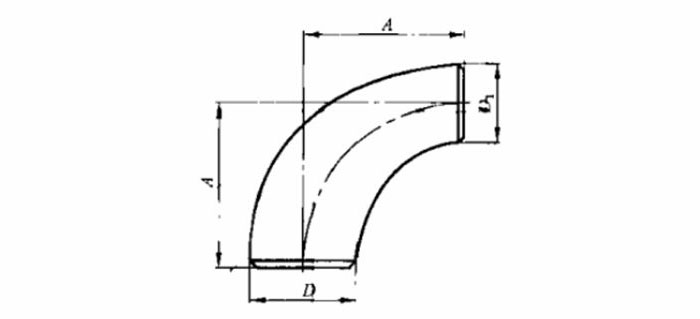

90 degree long radius auminium reducing elbow

We produce and supply 5083 H32,6061 T6 aluminium pipe elbow,The product type includes: Radius 90’s, Long Radius 45’s, Long Radius 180’s, Short Radius 90’s, Short Radius 180’s,etc. The whole production process is under the ISO9001:2001 strictly, It can be customized according to customer requirements.The 90 degree reducing aluminium elbow refers to the two calibers of the elbow which are not the same size. The function is to change the caliber of the pipe when making a 90 degree turn. The same effect as the size of the head, but the size of the head can not be used for steering.

The 5086 H32 90 degree aluminium reducing pipe elbow is the preferred hull material for small aluminum vessels or larger yachts. It has high strength and corrosion resistance, making it an excellent partner for yachts.

6061 T6 aluminium pipe elbow has very good machinability. It has excellent weldability and plating performance, and it has excellent toughness, good corrosion resistance, excellent oxidation effect and other excellent characteristics, and is very suitable for the marine environment.

Aluminum elbows have many advantages:

1. Lightweight, corrosion-resistant, non-toxic, suitable for marine and other environments.

2. The aluminum alloy elbow has good low temperature performance.

3 . Easy to install and use.

We use the advanced internal and external die cold extrusion process to manufacture aluminum elbows, the appearance of the produced aluminum elbows is more beautiful, the thickness is more uniform, the deviation is smaller, and the aluminum elbows have no defects such as cracks. In order to ensure that the aluminum elbows do not have scratches, our exported aluminum elbows are strictly packaged. First, the aluminum elbows are packed in cartons and then put into wooden boxes to ensure that the aluminum elbows do not bump or impact.

Short radius aluminum elbow refer to elbows whose curvature radius is 1 times the tube diameter; also known as 1D. The radius of curvature of the elbow is equal to 1 times the diameter of the pipe. Normally high pressure or high flow rates will use long radius aluminum elbows. Short radius is generally used in low-pressure fluids or where elbows are limited.

Aluminum elbows are used in a wide range of applications, including electric power, construction, mining, machinery, ships, etc., and welding elbows used in shipbuilding are divided into:

ES - short bend radius elbow

EL - long bending radius elbow

Nominal diameter:

ES - DN50-300

EL - DN15-300

Bending angle: ES type 90°, 180°, 60°, 45°, 30°, 15°

EL 45°, 90°, 180°, 60°, 30°, 15°

|

|||||

|

Nominal Dimension DN |

D | D1 | center to end A | ||

| I Series | Ⅱ Series | I Series | Ⅱ Series | ||

| 50×40 | 60.3 | 57 | 48.2 | 45 | 76 |

| 50×32 | 60.3 | 57 | 42.4 | 38 | 76 |

| 50×25 | 60.3 | 57 | 33.7 | 32 | 76 |

| 65×50 | 73.0 | 76 | 60.3 | 57 | 95 |

| 65×40 | 73.0 | 76 | 48.3 | 45 | 95 |

| 65×32 | 73.0 | 76 | 42.4 | 38 | 95 |

| 80×65 | 88.9 | 89 | 73.0 | 76 | 114 |

| 80×50 | 88.9 | 89 | 60.3 | 57 | 114 |

| 80×40 | 88.9 | 89 | 48.3 | 45 | 114 |

| 90×80 | 101.6 | 88.9 | 133 | ||

| 90×65 | 101.6 | 73.0 | 133 | ||

| 90×50 | 101.6 | 60.3 | 133 | ||

| 100×90 | 114.3 | 108 | 101.6 | 152 | |

| 100×80 | 114.3 | 108 | 88.9 | 89 | 152 |

| 100×65 | 114.3 | 108 | 73.0 | 76 | 152 |

| 100×50 | 114.3 | 108 | 60.3 | 57 | 152 |

| 125×100 | 141.3 | 133 | 114.3 | 108 | 190 |

| 125×90 | 141.3 | 101.6 | 190 | ||

| 125×80 | 141.3 | 133 | 88.9 | 89 | 190 |

| 125×65 | 141.3 | 133 | 73.0 | 76 | 190 |

| 150×125 | 168.3 | 159 | 141.3 | 133 | 229 |

| 150×100 | 168.3 | 159 | 114.3 | 108 | 229 |

| 150×90 | 168.3 | 101.6 | 229 | ||

| 150×80 | 168.3 | 159 | 88.9 | 89 | 229 |

| 200×150 | 219.1 | 219 | 168.3 | 159 | 305 |

| 200×125 | 219.1 | 219 | 141.3 | 133 | 305 |

| 200×100 | 219.1 | 219 | 114.3 | 108 | 305 |

| 250×200 | 273.0 | 273 | 219.1 | 219 | 381 |

| 250×150 | 273.0 | 273 | 168.3 | 159 | 381 |

| 250×125 | 273.0 | 273 | 141.3 | 133 | 381 |

| 300×250 | 323.9 | 325 | 273.0 | 273 | 457 |

| 300×200 | 323.9 | 325 | 219.1 | 219 | 457 |

| 300×150 | 323.9 | 325 | 168.3 | 159 | 457 |

| 350×300 | 355.6 | 377 | 323.9 | 325 | 533 |

| 350×250 | 355.6 | 377 | 273.0 | 273 | 533 |

| 350×200 | 355.6 | 377 | 219.1 | 219 | 533 |

| 400×350 | 406.4 | 426 | 355.6 | 377 | 610 |

| 400×300 | 406.4 | 426 | 323.9 | 325 | 610 |

| 400×250 | 406.4 | 426 | 273.0 | 273 | 610 |

| 450×400 | 457 | 480 | 406.4 | 426 | 686 |

| 450×350 | 457 | 480 | 355.6 | 377 | 686 |

| 450×300 | 457 | 480 | 323.9 | 325 | 686 |

| 450×250 | 457 | 480 | 273.0 | 273 | 686 |

| 500 ×450 | 508 | 530 | 457.0 | 480 | 762 |

| 500 ×400 | 508 | 530 | 406.4 | 426 | 762 |

| 500 ×350 | 508 | 530 | 355.6 | 377 | 762 |

| 500 ×300 | 508 | 530 | 323.9 | 325 | 762 |

| 500 ×250 | 508 | 530 | 273.0 | 273 | 762 |

| 600 ×550 | 610 | 630 | 559.0 | 914 | |

| 600 ×500 | 610 | 630 | 508.0 | 530 | 914 |

| 600 ×450 | 610 | 630 | 457.0 | 480 | 914 |

| 600 ×400 | 610 | 630 | 406.4 | 426 | 914 |

| 600 ×350 | 610 | 630 | 356.6 | 377 | 914 |

| 600 ×300 | 610 | 630 | 323.9 | 325 | 914 |